Cold chain management, a pivotal facet in industries spanning pharmaceuticals, food production, and logistics, has transcended the confines of conventional temperature monitoring. Far from being limited to temperature control alone, contemporary cold chain monitoring systems encompass an array of factors crucial to sustaining the integrity and quality of perishable commodities. In this discourse, we unveil the multidimensional landscape of cold chain management, highlighting how Thingsup, an innovative leader in IoT technology, employs wireless sensors and real-time insights to propel this evolution.

The Essence of Cold Chain Management:

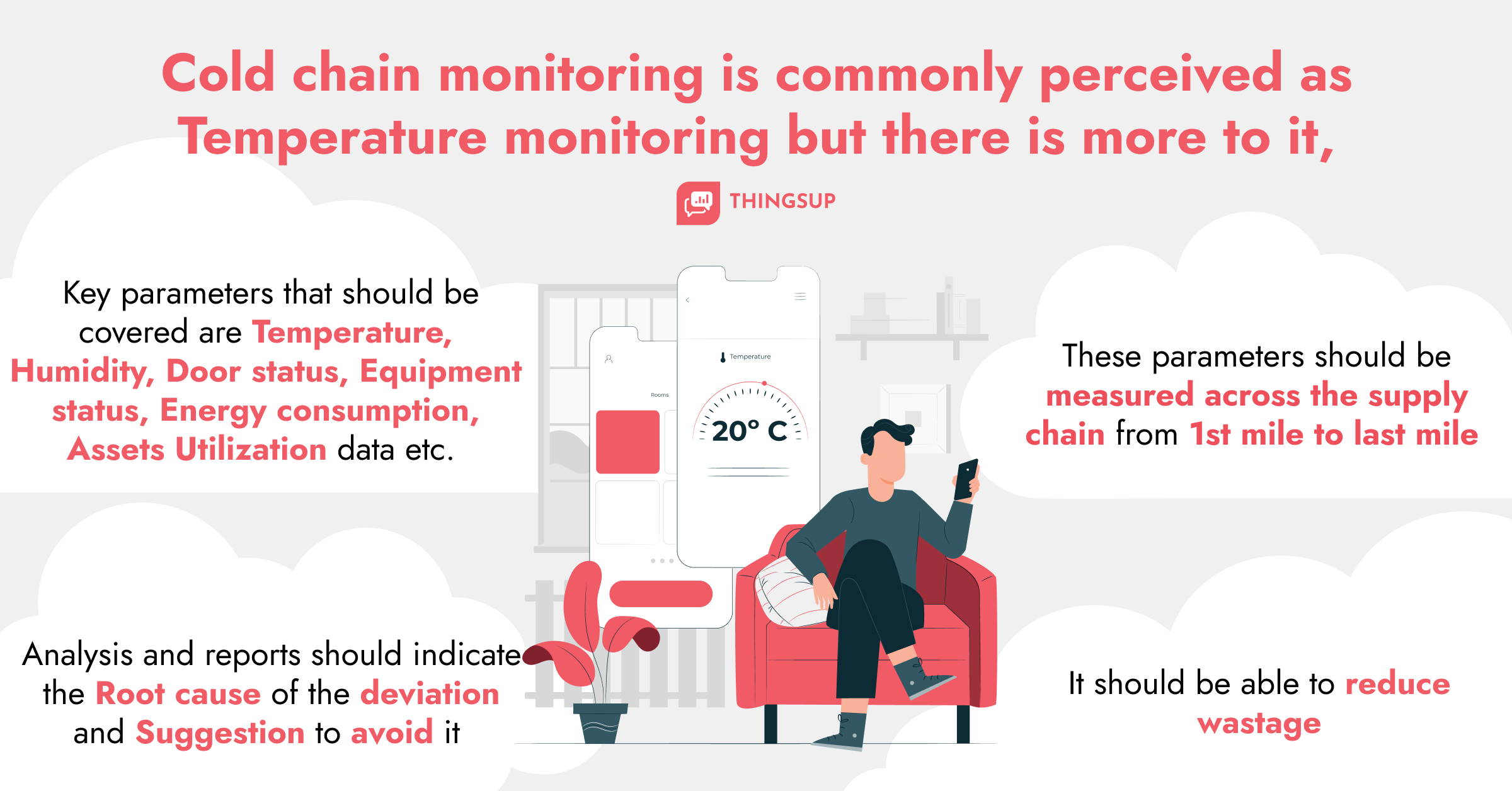

Beyond its conventional scope, cold chain management forms the bedrock of industries reliant on the secure transit and storage of temperature-sensitive merchandise. While the traditional focal point has been upholding a consistent temperature milieu along the supply chain, modern cold chain management takes on a more encompassing role. Robustly designed, it not only ensures adherence to optimal temperature thresholds but also encompasses humidity control, air conditioning unit assessment, compressor performance evaluation, the structural soundness of cold chain enclosures, and vigilance against external temperature vicissitudes.

Key parameters for Cold chain monitoring

- Temperature and Beyond

Temperature surveillance merely scratches the surface of a comprehensive cold chain management paradigm. It incorporates an array of sensors and data points to offer a panoramic vista of the conditions that impact product quality. In tandem with temperature monitoring, these sensors persistently track humidity levels to forestall moisture-induced deterioration. Furthermore, air conditioning unit status is vigilantly monitored, upholding the zenith of climate control efficiency. Scrutiny of compressor activity ensures sustained cooling, obviating any deviations that might imperil product integrity. Meanwhile, a meticulous evaluation of the structural resilience of cold chain containers safeguards against physical impairment that could compromise insulation and temperature uniformity.

2.Real-Time Cold Chain Management:

A hallmark of the cold chain management evolution is the advent of real-time systems, proffering instantaneous insights into supply chain conditions. Such systems furnish stakeholders with real-time access to dynamic data encompassing temperature, humidity, and other pivotal metrics. This unfettered visibility empowers prompt decision-making and timely interventions in the event of anomalies or deviations. By triggering real-time alerts, these systems notify pertinent personnel of condition shifts, facilitating immediate remedial measures. This pre-emptive strategy drastically mitigates the risk of product spoilage and wastage, concomitantly amplifying product quality and customer gratification.

3. Wireless Sensors:

Central to modern cold chain management systems are wireless sensors, veritable vanguards of transformative potential. These diminutive yet supremely sensitive sensors are strategically positioned throughout the cold chain ecosystem. Seamless synchronization with the central monitoring platform permits real-time data transmission and updates. The wireless nature of these sensors circumvents the need for intricate wiring installations, fostering facile scalability. Rapid sensor deployment expedites access to invaluable insights sans cumbersome setup protocols.

The integration of wireless sensors within cold chain management engenders precision augmentation and affords leeway in sensor placement. This flexibility ensures even the most secluded recesses of cold chain containers are comprehensively surveyed, obviating potential blind spots. Furthermore, wireless sensors portend fiscal benefits by reducing maintenance requisites and curtailing susceptibility to physical infrastructure impairment.

Conclusion

Cold chain management has evolved far beyond conventional temperature tracking, morphing into a comprehensive framework incorporating temperature, humidity, air conditioning, container robustness, and external influencers. This transformation finds its driving force in real-time cold chain management systems, fortified by the prowess of wireless sensors. As industries increasingly recognize the imperative of preserving product quality and authenticity, the significance of an all-encompassing cold chain management strategy grows ever more palpable. With each technological stride, enterprises can rest assured that their perishable commodities traverse the supply chain trajectory with meticulous precision, securing consumer safety and underlining industry eminence.