In the dynamic realm of Industry 4.0, the fusion of cutting-edge technology with manufacturing processes has ignited a profound transformation. Recent statistics underscore the remarkable influence of this fourth industrial revolution, while the latest news highlights its continuous expansion and innovation.

Statistics Revealing the Reach of Industry 4.0

- By 2027, Industry 4.0 is poised to generate an immense market valued at $1.5 trillion, emphasizing its vast economic potential.

- The adoption of Industry 4.0 technologies is forecasted to amplify global productivity by an astounding 30% by the year 2030.

In this comprehensive exploration, we embark on a journey through the landscapes of Industry 4.0, delving into compelling use cases, each brought to life with detailed examples and complemented by pertinent images. These real-world applications provide a vivid illustration of the transformative prowess of Industry 4.0, where cutting-edge technologies are revolutionizing industries and reshaping the future of manufacturing.

Exploration of Industry 4.0 Use Cases

Use Case 1: Smart Factory Automation

The indelible mark of Industry 4.0 is boldly etched in the domain of smart factory automation. Here, advanced robotics and AI-driven systems seamlessly collaborate with human workers. For instance, envision a fully automated production line that possesses the capability to self-optimize in real-time based on shifting demand patterns. Such a scenario ensures the efficient utilization of resources, a reduction in operational costs, and a swifter time-to-market.

Use Case 2: Predictive Maintenance

Predictive maintenance, a hallmark of Industry 4.0, comes to life through the deployment of IoT sensors and the prowess of machine learning algorithms. These technologies empower machines to forecast their maintenance requirements. Consider a manufacturing plant where sensors vigilantly monitor the condition of critical equipment, such as a conveyor belt. Advanced algorithms meticulously scrutinize this data, sounding maintenance alerts well before any mechanical breakdown occurs. The result? A significant reduction in downtime and cost savings.

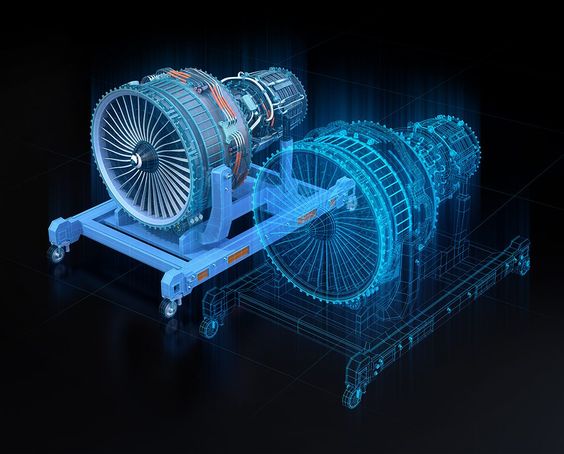

Use Case 3: Digital Twins

Digital twins stand as a revolutionary application of Industry 4.0, where physical assets find their digital doppelgängers. In an aerospace context, picture a digital twin meticulously mirroring an aircraft engine. This virtual counterpart perpetually collects real-time data through sensors. Engineers leverage this digital replica to monitor performance, anticipate potential issues, and conduct simulations for optimization. The outcome is not only safer but also more efficient operations.

Use Case 4: Supply Chain Transparency

Industry 4.0 redefines supply chain transparency, particularly through the innovative adoption of blockchain technology. Consider a use case within the food industry where blockchain traces the journey of products from farm to table. Consumers have the power to scan a QR code on a food package to trace its origin, ensuring safety and authenticity, while simultaneously combatting fraud and minimizing waste.

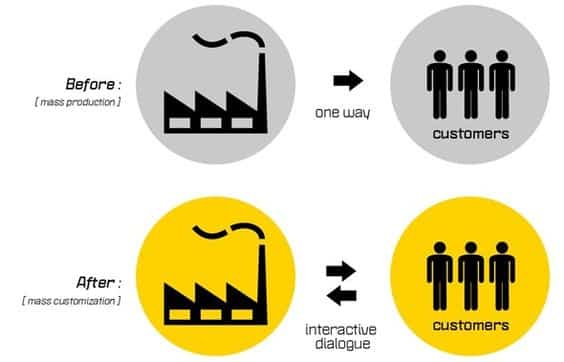

Use Case 5: Customized Production (Mass Customization)

Mass customization, made attainable by Industry 4.0, ushers in an era where products can be tailored to individual customer preferences on a grand scale. Imagine the automotive sector, where customers embark on a journey of customization by selecting various features of their vehicle online. Robots and flexible manufacturing systems then orchestrate the assembly of the vehicle, meticulously following the customer’s unique specifications. The outcome is the provision of personalized products at a scale that was once unimaginable.

Conclusion

In conclusion, these Industry 4.0 use cases invite us to glimpse a landscape where technology is not merely a tool but a transformative force. With smart factory automation, predictive maintenance, digital twins, supply chain transparency, and mass customization as guiding stars, the fourth industrial revolution propels us toward a future where innovation knows no bounds, efficiency reigns supreme, and the horizons of possibility stretch ever further.