As advanced technologies are used in every industry, temperature monitoring systems are becoming popular globally. These systems are completely ready to work with advanced technologies.

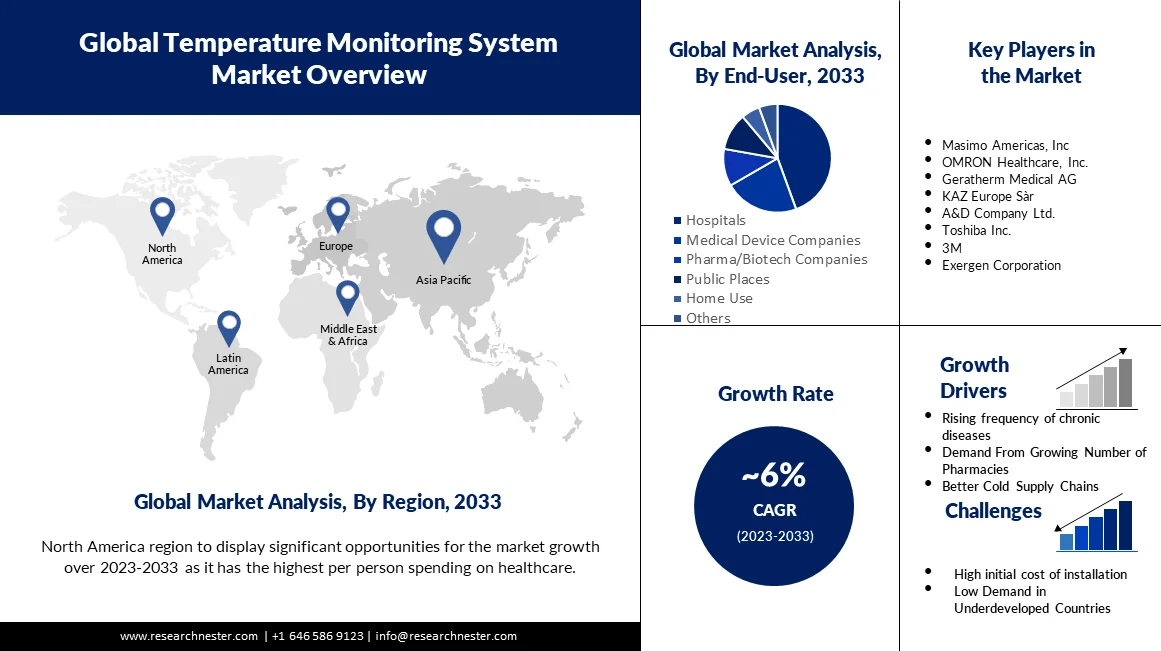

According to a report by Researchnester, the market size of temperature monitoring system was valued at USD 3.17 Billion in 2023. This market value is estimated to increase to USD 6.52 Billion by 2036.

Here it is:

This expansion is being driven by many factors, such as advancement in wireless monitoring, demand for environmental control within the premises, and integration of AI technology. Industries such as healthcare, manufacturing, food and beverages, and automotive are using these technologies extensively to ensure safety, efficiency, and regulation compliance.

And all this has been possible because of IoT technology. Today, in these industries, devices equipped with this technology can connect to local WiFi and record equipment and other data, which can then be accessed remotely.

In this blog today, we will discuss the role of temperature monitoring systems in different industries and how many types there are. Overall, we will deeply analyze each factor and see the advantages of these systems in which industries, what their limitations are, and what their applications are.

All in all this is going to be a power packed blog that will give you an opportunity to know temperature monitoring systems closely.

What is Temperature Monitoring?

In any simple environment, process, or premise in which the temperature is measured or recorded so that it can be controlled is called temperature monitoring. Temperature sensors are used for temperature monitoring. These sensors are devices that convert temperature into electrical signals so that the temperature can be recorded and analysed.

There are many industries where temperature monitoring is done to keep the process safe. This mainly includes food and beverage, pharmaceutical, petrochemical, and HVAC.

Its main purpose is to maintain or control the temperature within a certain limit according to specific requirements. In business, the temperature in the process (including production, transportation, storage, etc.) or the temperature in the environment is constantly monitored by temperature sensors. If the temperature anywhere exceeds or falls below a specified limit, then the user gets the information. Then, any corrective action can be taken in time.

What are Temperature Monitoring Systems?

Temperature monitoring systems are temperature detectors that convert the temperature of a process or environment into a readable form. This temperature is then analysed and required action is taken. With the right temperature monitoring system you can measure critical temperatures at different sites, data centres, server rooms, in the cold chain, etc.

The Role of Temperature Monitoring Across Industries

Healthcare Industry

When it comes to the healthcare sector, temperature monitoring is a vital component of the medical refrigeration system. Medicines, vaccines and blood samples need to be kept within an approved temperature range to maintain their safety and efficacy.

Regular temperature monitoring reduces the chances of products spoiling to a minimum or none. By doing this, healthcare providers can save money in the long run.

The World Health Organization has highlighted that if healthcare products such as vaccines are not kept at the correct temperature, the chances of them spoiling increase, which in turn affects the public health efforts of governments.

Cold Chain Management: Vaccine storage and transport must strictly adhere to set temperatures. This temperature range is often between 2°C and 8°C. According to the CDC, improper vaccine storage affects 37% of vaccines globally, resulting in losses worth billions.

Hospital Use: In hospitals, temperature monitoring is mostly used in blood banks, operating rooms, and incubators. Here, real-time monitoring systems ensure compliance with strict guidelines set by the U.S. FDA.

Food and Beverage Industry

In the food and beverage industry, temperature monitoring is not just a good idea but a necessity of the day. A small mistake in food storage can spoil the food and promote bacterial growth, which puts consumers at risk of health hazards. If consumers suffer losses, it will directly affect the reputation of your food business.

According to an estimate by the FDA, due to a lack of proper monitoring of the cold chain, approximately 48 million Americans suffer from foodborne illnesses.

To avoid all these issues, food manufacturers have to rely on technology, the most important of which is temperature monitoring systems. These prevent food from spoiling by alerting business owners to fluctuating temperatures all the time.

Cold Storage: Maintains optimal temperatures during transportation and storage. It also ensures compliance with regulations like the Hazard Analysis and Critical Control Points (HACCP).

Food Processing: Accurate monitoring is strictly required during cooking, cooling, and packaging to maintain the nutritional value.

Real-Time Alerts: Refrigerated trucks have IoT-enabled sensors that provide real-time data and alerts about food. This has reduced food spoilage rates by up to 15%, as seen in Walmart’s cold chain system.

Manufacturing Industry

In the manufacturing industry, it is very important to have a proper heating and cooling system. Because the efficiency of workers in the manufacturing line is greatly affected by the optimal temperature. In such a situation, temperature monitoring systems are very important to maintain the environment of the premises.

Aerospace and Automotive: Metals and plastics are used the most in the aerospace and automotive industry. They perform different functions based on their heating and cooling. Boeing uses a high tech temperature monitoring system to ensure composite materials can be easily fixed. This allows the parts of the airplane to be cooled or heated as needed.

Chemical Production: Chemicals also need a set temperature to give the best performance. The chemical processes that are used to make the products safely often need precise temperature control. Even a change of 1-2°C can be fatal.

Machine Maintenance: Many times, the equipment installed in the machinery gets very hot during work. In this case, it breaks down without any warning, which is very expensive to repair. With the help of predictive temperature tracking, industries can get information in advance about the possibility of machinery breakdown. This can save a lot of their expenses.

Data Centres

According to one report, the average cost of unplanned failures in data centers is $8,850 per minute. And one of the biggest reasons for these failures is overheating.

Data centers generate excessive heat, especially in the IT industry, which works 24*7, so there is a high chance of failure of data center equipment. Here, temperature monitoring is very important to prevent equipment failure. If any equipment failure happens once, then businesses can lead to costly repairs, data loss and corruption.

IoT devices are a great help here; they provide:

Real-Time Monitoring: IoT-based temperature sensors alert whenever the temperature on servers exceeds the threshold limit, which can prevent equipment from getting damaged.

Energy Efficiency: Using real-time temperature data to improve cooling systems lowers the cost of energy use. Google, for example, uses AI-driven tracking to cut the amount of energy it needs to cool its data centers by 40%.

Agriculture Industry

Smart soil management is the key to smart farming as it helps farmers produce the most food possible. Sensors that measure the temperature and humidity of the soil are the best tools to reach this goal. These sensors get accurate information about the conditions of the land, which helps farmers change how they farm smartly and effectively. Farmers can get the most out of irrigation, avoid waste, improve crop health, and boost yields by using these tools in their work.

Greenhouse Management: Sensors monitor the environmental temperature and soil humidity in real-time and optimize these factors according to the requirements. This improves the growth of plants. According to a research report, smart greenhouses can increase crop yield by up to 25% as compared to traditional methods.

Cold Storage for Crops: With the help of IoT devices, crop quality can be maintained by properly controlling the temperature during storage. The Food and Agriculture Organization (FAO) estimates that 14% of the world’s food is lost post-harvest, with inadequate storage being a key factor.

Livestock Monitoring: Preserving steady temperatures is important for keeping animals healthy and productive, and it also cuts down on losses caused by heat stress.

Key Features of Temperature Monitoring Systems

Real-Time Monitoring

If we talk about modern temperature systems, then real-time monitoring is its backbone. With its help, businesses can instantly observe fluctuations in the temperatures of their equipment. This gives information before any equipment failure occurs. These systems use sensors to measure temperature consistently. These sensors send data instantly to central systems so that information can be collected instantly.

Custom Alerts

Businesses need to make proactive decisions to get ahead of competitors. And to take such instant decisions, a customizable alert system is needed. These systems notify users instantly whenever the temperature deviates even slightly from its set patterns.

Alerts can be customized to suit business requirements. These alerts are delivered to users via text messages, emails, and automated calls to help them make the right decisions at the right time and in the right way.

Data Logging

Data logging is essential for conducting audits, compliance, and performance evaluations. Temperature monitoring systems that lack data logging capabilities can be very efficient for businesses. These systems store temperature data at the premises. This temperature history is then further used to review the trends and any anomalies in the system, or check compliance with standards. Some of these systems also provide cloud based storage that helps in easy access and long term retention.

Wireless Connectivity

Whenever remote monitoring is to be done, wireless connectivity is very useful. It brings flexibility to the whole process and brings convenience to the workstation. It helps in controlling temperature systems while sitting in one place.

With the help of IoT integration, temperature sensors can easily communicate with cloud platforms. This allows businesses to collect temperature data from any location. This saves both time and resources.

Battery Backup

Businesses may have to face power outages at any time. In this way, a robust battery backup can ensure that all systems can perform their functions without stopping.

Power failures are most harmful to businesses in temperature sensitive environments. In this way, battery backup helps with uninterrupted temperature monitoring along with notifying the users to reduce potential risks even when the main power supply is unavailable.

Smooth Integration with Existing Systems

Many businesses need to integrate monitoring systems because they feel that this is a very complex process. And yes, it is. For that, a temperature monitoring system should be chosen that can be easily integrated with existing hardware and software. Many temperature monitoring systems are designed to integrate with existing equipment, such as HVAC and other inventory management software.

User Friendly Interface

The simpler the interface, the easier it will be to use. A simple and smooth interface simplifies everything from system setup to operations. Systems with a simple interface can be operated easily by even non-technical users or new users.

User-friendly dashboards display temperature data visually using graphs, color codes, and alerts. This reduces the learning curve and ensures that employees can quickly adapt to the system.

Types of Temperature Monitoring Systems

With the advancements in technology, temperature monitoring systems have also evolved. New systems have come into the market to meet the needs of businesses. These are:

Manual Temperature Monitoring Systems

Manual temperature monitoring is a traditional form of monitoring that uses basic devices. These include mercury thermometers, alcohol thermometers, or bimetallic strips to measure and record the temperature.

How Does the Manual Temperature Monitoring System Work?

The user must physically record the temperature on the device. For example, a bimetallic thermometer measures temperature by using two metals. These metals expand at different rates and give a simple analog reading.

Advantages

Cost-Effective: These systems are quite cost effective. There is little initial investment in it, so startups with low investment can use it.

Low Maintenance: There is not much maintenance cost for these systems.

No Power Dependency: These temperature monitoring devices can work without electricity or batteries.

Limitations

Labor-Intensive: It requires recording readings manually, which may require hiring extra labour.

Inaccuracy Risks: Although these systems do not make any mistakes in showing temperature, there is a high chance of human error during manual reading.

No Real-Time Monitoring: It does not alert if there is any rapid change in temperature, which is why real time temperature monitoring cannot be done.

Applications

These systems are mostly used in small scale applications. Such as household freezers or simple laboratory setups where there is not much budget or there is no need for advanced technology.

Digital Temperature Monitoring Systems

Digital temperature monitoring systems are an upgraded version of manual systems. As compared to manual systems, it provides better accuracy, is easier to use, and includes some better features such as data logging.

How Does the Digital Temperature Monitoring System Work?

Digital temperature monitoring systems have digital thermometers that have sensors such as thermistors or thermocouples to measure the temperature. They measure the temperature and display their readings on LED or LCD screens. Some advanced models are also there that store data as well as have downloadable logs.

Advantages

Higher Accuracy: These systems are quite accurate. They can measure temperature with a precision of up to 0.1°C.

Ease of Use: Its interface is simple, so anyone can easily use it. It also has digital readouts which makes readings easy to read and note.

Data Logging: They can store temperature, which makes it easy to analyze the temperature.

Limitations

Limited Connectivity: Real-time remote monitoring is only possible if they are paired with additional systems.

Power Dependency and Higher Costs: External power sources or batteries are required to use them. This causes additional expense, and their cost increases a bit.

Applications

They are mostly used in laboratories, food storage facilities, and industrial processes. Especially where accuracy and data retention are of higher importance

IoT-Based Temperature Monitoring Systems

IoT-based systems are among the most advanced temperature monitoring systems. These systems use interconnected sensors and devices to provide real-time data and actionable insights.

How Does IoT-Based Temperature Monitoring Systems work?

IoT-enabled sensors such as thermocouples or RTDs are installed to measure temperature in critical areas of a premise. The specialty of these sensors is that they can transfer data directly to IoT platform without any complex systems. This data is later analyzed and displayed on the dashboard or mobile apps.

Advantages

Real-Time Monitoring: These systems are capable of monitoring any equipment in real time. These provide instant updates and alerts so that the required action can be taken immediately.

Remote Access: With the help of these systems, data can also be generated remotely with the help of the internet.

Predictive Maintenance: These systems have AI technology that can predict the time of failure of any equipment. It is especially beneficial in the manufacturing industry.

Scalability and Integration: They are scalable for large-scale industrial applications. They can also be easily integrated with other systems such as HVAC, supply chain management, and security systems.

Limitations

High Initial Costs: The initial costs for installing these systems are quite high. It may be difficult for small scale and startups to afford it.

Connectivity Dependency: A reliable internet connection is required to use these systems.

Complexity: Setting up these systems is not that easy. Technical expertise is required for this. Apart from this, their maintenance is also quite costly.

Applications

Healthcare: IoT based monitoring systems are used a lot in the healthcare industry. These systems are quite beneficial when vaccines are transferred from one place to another or proper storage is required.

Food and Beverage: In the food industry, when products are transported, some products are kept at a set temperature. In this case, IoT monitoring systems are quite helpful in maintaining those temperatures.

Data Centres: Data centres require cooling systems to prevent overheating. These IoT monitoring platform are needed to maintain the temperature of those systems.

What to Look for While Selecting a Temperature Monitoring System?

Accuracy

The accuracy of temperature monitoring systems can be both beneficial and detrimental to a business. Even a minor deviation can lead to major consequences like product spoilage, equipment failure or even regulatory violations. Some industries, such as pharmaceuticals and food storage must follow strict temperature-related guidelines. Even a small mistake can cause significant damage.

For pharmaceutical industries, agencies like the CDC have made it mandatory that the accuracy of devices must be ±0.5°C.

The FDA’s Food Safety Modernization Act (FSMA) for the food and beverages industry emphasizes monitoring at critical control points to avoid foodborne illnesses.

Durability

Temperature monitoring systems need to be durable, as these systems operate in very robust environments such as industrial plants, outdoor areas in direct sunlight, cold storage warehouses, etc. A durable system can operate well in all conditions without compromising performance.

There are some environments where there are continuous fluctuations which increase the risk of damage to the equipment. In such a situation, a durable system prevents frequent breakdowns of the equipment. In addition, some systems come with IP67 ratings which protect against water and dust. These systems are better for outdoor environments.

Range of Operations

Different applications require systems capable of measuring temperatures across a wide spectrum. For example, cryogenic storage for vaccines demands ultra-low temperature monitoring, while industrial processes may involve high heat.

If the system’s range is inadequate, it might fail to provide accurate readings or function altogether in extreme conditions.

Connectivity Options

The temperature monitoring system should be advanced in terms of connectivity and equipped with modern technology. Modern connectivity features like Wi-Fi, Bluetooth, and IoT integration make it easier to monitor temperatures remotely and manage data efficiently.

Wi-Fi enabled systems help managers to access the temperature data across multiple places even from a single dashboard.

Moreover, if your system is integrated with IoT, it will help you with predictive maintenance. You will get to know about any problem before it occurs, and be able to resolve it in time.

Strong Battery Life and Power Backup

Uninterrupted temperature monitoring is a must for some businesses. Power outages can be damaging. So when choosing a monitoring system, make sure it has a long battery life and can operate without interruption even in remote areas where there is power outage.

For remote areas where power sources are unreliable, battery operated systems with strong power backup are the best option.

Compliance and Certification

The temperature monitoring system should comply with industry standards, be reliable, fit as per the laws, protect the business from penalties, and keep your reputation intact.

There are certain certifications that your system must have. It includes ISO 9001, FDA, CE, or HACCP. These certifications indicate that your system complies with quality and safety standards.

Scalability

The temperature monitoring system should be scalable. It should grow along with your business. If you ever need to install additional sensors in your system, set it up at a new location or add any new functionality to it, then it can be done easily.

Many times, when you think of expanding your business, your system needs help to expand. So keep in mind that the system should expand according to the new facilities and advanced features can be added to it whenever required.

What’s Next?

As technology becomes more advanced, we will see more potential innovations in these systems. They are changing the way businesses operate, reducing risk, and opening up new opportunities.

Whether it’s manufacturing, storing, or transporting life-saving vaccines in the healthcare industry or optimizing the environment and processes in manufacturing plants, these systems play an important role.

If you, too, want to implement or upgrade a temperature monitoring system in your business, then this is the right time. Do not be confused at all, because this is not just an investment, it is a commitment to quality and reliability.