Cold storage facilities are an important part of temperature sensitive goods such as food, pharmaceuticals, and chemicals. However, maintaining accurate environmental conditions is not an easy task. The slightest temperature deviations or fluctuating humidity will result in product spoilage, financial losses and harm the company’s reputation. Here, an IoT Cold Storage Monitoring System offers real-time insights, automation, and peace of mind.

This blog will describe how IoT remote monitoring technologies revolutionize cold chain monitoring operations across the organizations.

The Real Challenges of Cold Storage Operations

Cold storage is not just about keeping things cold. It is about consistency, precision, and reliable results. Businesses face many challenges, like:

Temperature Fluctuations

A small discrepancy in storage unit temperature will destroy perishable goods. For example, vaccines lose effectiveness when exposed to temperatures outside the recommended area, but frozen foods become rotten when temporarily thawed.

High Energy Costs

Cold storage facilities are energy-intensive. The required constant low-temperature operations lead to dramatic utility expenses, causing energy efficiency a top priority.

Outdated Manual Monitoring

Manual checks are not only labor intensive but also prone to human error. Employees might miss subtle changes in conditions, leading to costly consequences.

Regulatory Compliance

The food production sector and healthcare sector must comply with FDA, HACCP and WHO regulations. Non-compliance could lead to product recalls, large fines, or even legal action.

Equipment Failures

Cold storage facilities depend fully on the operation of their refrigeration units. Failure in the compressor system, together with unexpected power disruptions, can lead to complete devastation of stored merchandise.

Data Overload

The analysis of enormous temperature and humidity datasets becomes too complex when handled by manual methods. A business becomes unable to organize gathered information when it lacks appropriate tools.

Security Concerns

Unauthorized access or tampering with equipment can harm product integrity, posing risks to both compliance and safety.

How Modern Cold Storage Monitoring Systems Solve These Problems?

The development of modern technology has produced improved, efficient systems for monitoring cold storage facilities. These solutions offer direct solutions to deal with the mentioned difficulties:

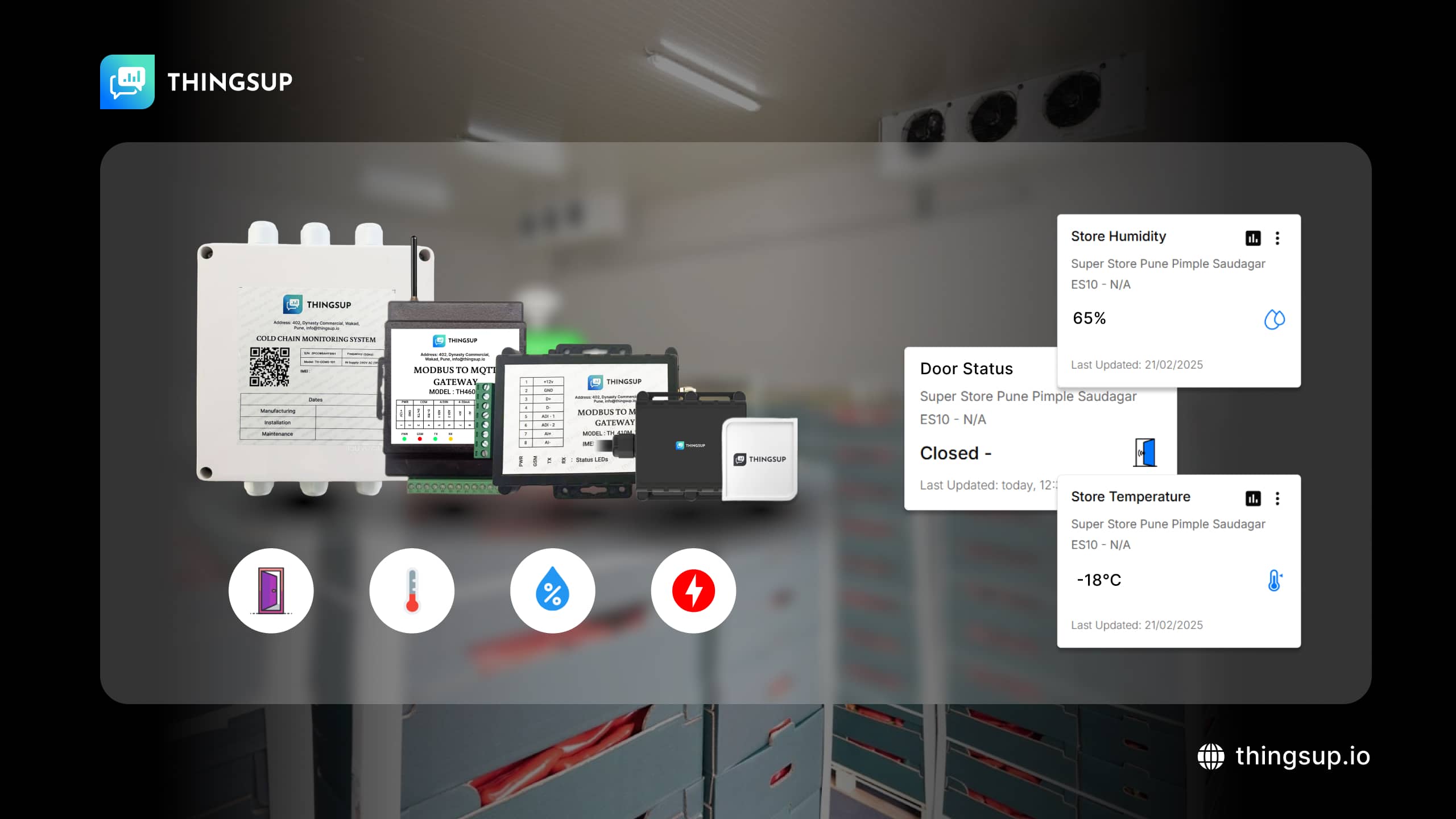

IoT-Enabled Sensors

The facility gets constant temperature and humidity monitoring with wireless sensors set across its entire area. These devices supply current data patterns to prevent any system lapses.

Cloud-Based Platforms

All collected data is securely stored in the cloud, making it accessible from anywhere at any time. The cloud simplifies team collaboration so that organizations can work together and audits become less complex.

Instant Alerts and Notifications

No more waiting for manual checks! The system generates alert messages through SMS text or email platforms and mobile applications that produce immediate notifications about system errors so that you can respond quickly.

Predictive Maintenance

Systems today apply AI together with machine learning capabilities to predict equipment failures that might happen before they happen. Methods used ahead of time protect system operations and keep equipment within their designated lifespan.

Remote Monitoring Dashboards

Your cold storage facility monitoring appears in a single dashboard that provides complete status details. Through a single interface, you can monitor all your warehouses, whether they are one or several locations.

Compliance Made Easy

The combination of automated logging systems and reporting functions guarantees your operations comply with industry specifications at each moment. Your business will possess complete documentation available when auditors perform their examinations.

Energy Optimization Tools

The monitoring system tracks user patterns to manage cooling systems automatically, which decreases operational expenses while upholding operational requirements.

Enhanced Security Features

Biometric scanners, together with RFID tags, function as access control systems to let authorized employees gain entry into restricted zones. An additional protective measure prevents unauthorized personnel from tampering with or attempting to steal products inside secure areas.

Why You Need a Cold Storage Monitoring System

Do any doubts remain about acquiring monitoring system technology? A monitoring system represents an essential advancement for your business because it provides multiple benefits:

Protect Product Quality

Your business will achieve product freshness and quality compliance through the maintenance of stable environmental conditions.

Save Money

Cold storage monitoring systems generate financial savings through several efficiency improvements that create positive returns on their initial investment. The prevention of spoiled products enables financial savings because spoiled materials become less costly.

Boost Operational Efficiency

The automation process removes time-consuming manual work, so your team becomes available for more impactful work activities.

Stay Compliant

The system generates automated reports, which ease the process of fulfilling regulatory requirements through documentation.

Minimize Downtime

Fast detection of problems makes it possible to handle issues when they first start so your operations avoid disruptions.

Scale with Ease

Modern business systems will accommodate expansion into new facilities along with extra location openings.

Go Green

Your business becomes more environmentally sustainable because energy optimization reduces carbon emissions.

Applications Across Industries

Cold storage monitoring solutions demonstrate universal functionality as they service multiple industries simultaneously.

Industry | Application |

| Food & Beverage | Ensuring freshness of fruits, vegetables, meat, dairy, and frozen foods. |

| Pharmaceuticals | Maintaining precise conditions for vaccines, medicines, and biological samples. |

| Chemicals | Storing chemicals that require specific temperature ranges to prevent degradation or reactions. |

| Logistics | Monitoring temperature-controlled shipments during transportation to avoid spoilage. |

| Retail | Managing walk-in freezers and chillers in supermarkets and grocery stores. |

| Research Labs | Preserving specimens and conducting experiments under controlled conditions. |

IoT Remote Monitoring: Transformational Cold Chain Management

The IoT has changed cold chain management by providing unmatched visibility and control. Remote monitoring through Internet of Things technology brings these changes to the market:

| Feature | Benefit |

| End-to-End Visibility | Track temperature, humidity, and location at every stage of the supply chain. |

| Real-Time Tracking | GPS-enabled sensors provide live updates on shipment locations and conditions. |

| Automated Documentation | Automatically generate logs and reports for compliance and audits. |

| Smart Containers | Refrigerated containers equipped with IoT sensors maintain optimal conditions during transit. |

| AI-Powered Insights | Advanced analytics identify trends, predict risks, and suggest improvements. |

| Blockchain Integration | Create an immutable record of transactions and conditions for enhanced trust and traceability. |

| Mobile Accessibility | Monitor operations remotely via smartphones or tablets. |

| Customizable Alerts | Set thresholds tailored to your needs and receive instant notifications for anomalies. |

Cost-Benefit Analysis: Why Investing in a Monitoring System Makes Sense

To further illustrate the value of a cold storage monitoring system, let’s break down the costs and benefits:

| Factor | Without Monitoring System | With Monitoring System |

| Initial Investment | Low upfront cost | Moderate upfront cost |

| Operational Costs | High due to energy inefficiency and spoilage | Reduced through energy optimization and spoilage prevention |

| Downtime | Frequent due to undetected equipment failures | Minimized with predictive maintenance |

| Compliance | Manual effort required, risk of non-compliance | Automated, ensuring full compliance |

| Product Losses | High due to temperature fluctuations | Significantly reduced |

| Scalability | Limited | Easily scalable |

| ROI | Low | High |

Final Thoughts: Why a Cold Storage Monitoring System Is Worth It

The cost of a cold storage monitoring system is not just about protecting your product. It’s about safeguarding your reputation, optimizing resources, and staying competitive in today’s fast-paced market. These solutions provide a good ROI by tackling important problems, raising efficiency, and guaranteeing compliance.

The use of outdated techniques should not constrain your business performance. Govern your cold storage operations through technological power. IoT-based remote monitoring enables customers to see their products throughout their entire journey and boost product quality standards, leading to superior value delivery.

Take the Next Step Today

Your business is ready to experience operational change in cold storage systems. Explore our cold storage monitoring solutions, which help organizations reach their goals. Contact us now to learn more!

.