To succeed in the manufacturing industry, you must focus on two basic factors: uninterrupted production and maintaining equipment efficiency.

Traditionally, manufacturers had to incur significant losses due to equipment failures. However, since the emergence of IoT platform, technologies have become smarter, and manufacturing factories have become modern.

Predictive maintenance, powered by IoT technology, enables manufacturers to preemptively address equipment malfunctions, minimize downtime, and save significant operational costs.

This blog post will give you a full picture of how IoT platforms enable predictive maintenance in manufacturing. We will discuss its parts, the technologies that make them work, the pros and cons, and the trends that will happen in the future.

What is Predictive Maintenance?

Predictive maintenance is a proactive approach that uses real-time data analytics to obtain accurate information about equipment. This information tells when equipment is about to fail.

Unlike preventive maintenance, which relies on predefined schedules, predictive maintenance is based on actual equipment conditions. It helps reduce unnecessary maintenance activities and prevent unexpected equipment breakdowns.

IoT-enabled platforms let manufacturers monitor the health of their assets and fix issues before they get worse.

Differences Between Reactive, Preventive, and Predictive Maintenance:

| Maintenance Type | Description | Cost Implications | Effect on Downtime |

| Reactive Maintenance | Repairing after equipment failure | High repair and downtime costs | Results in high downtime |

| Preventive Maintenance | Scheduled maintenance based on set intervals | Lower repair costs but higher unnecessary downtime | Reduced but unnecessary downtime |

| Predictive Maintenance | Maintenance based on real-time data and failure predictions | Optimized costs, as repairs are done only when needed | Significantly reduces unplanned downtime |

According to McKinsey reports, using predictive maintenance in manufacturing can cut costs by 20 to 30 percent, extend the life of equipment, and cut down on their breakdowns by almost 50 percent.

IoT platforms make this possible by combining different technologies to track things in real-time and make predictions.

What is The Role of IoT Platforms in Predictive Maintenance?

IoT platforms play a crucial role in predictive maintenance. In manufacturing industries, they connect machines, sensors, and systems on the factory floor.

This allows for easy real-time data collection, processing, and analysis, and manufacturers can get information about equipment failure issues in advance.

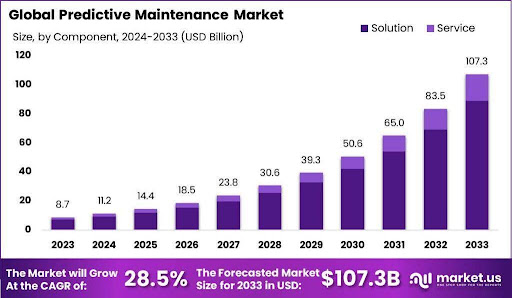

Here is the data showing how predictive maintenance is quickly becoming popular in the market:

Here’s how IoT platforms contribute to predictive maintenance:

Continuous Data Collection

IoT sensors are built into equipment to monitor temperature, vibration, pressure, and humidity. These sensors continuously collect information about working equipment, which is then sent to IoT platforms for further analysis.

For example, an IoT-enabled sensor connected to a motor can check the vibration level, which can help find imbalances or misalignments that could mean something is about to break.

Data Processing and Analysis through AI/ML Algorithms

Once the equipment data is collected, IoT platforms analyze it using AI and machine learning algorithms. These algorithms are specially designed to identify the equipment’s patterns and trends.

It provides information about the equipment and whether it works fine or deviates from its normal operating parameters. This then signals the possibility of future equipment failure, if there is any.

For example, the GE Predix platform uses AI to track and analyze data about equipment health, show potential failure points, and suggest the best maintenance method. Over time, IoT platforms can make failure predictions more accurate by processing huge amounts of data, helping businesses make better decisions.

Edge Computing for Fast Decision-Making

Using edge computing brings data processing closer to the equipment, reducing latency and enabling real-time decision-making.

The application of edge computing in predictive maintenance is especially helpful when time is the main concern. Edge computing, for example, ensures that corrective actions can be taken immediately without the need for data to travel to the cloud and back again. This computing type is particularly useful when a critical piece of machinery shows signs of imminent failure.

In industries such as automotive manufacturing, where quick reaction times can prevent assembly line shutdowns, this is especially relevant due to the importance of their reaction times.

Integration with Digital Twins for Improved Efficiency and Better Decision Making

Digital twins are virtual replicas of physical equipment that provide real-time insight into operating conditions. Using IoT data, the digital twin mirrors the physical object’s behavior, which allows manufacturers to simulate maintenance scenarios and predict the impact of various operating conditions on the equipment’s health.

For example, in aerospace manufacturing, digital twins monitor engine performance, providing highly accurate predictions about when maintenance should be performed.

What are the Core Technologies Behind IoT-Driven Predictive Maintenance Systems?

IoT-enabled predictive maintenance is based on a few key technologies, each of which plays a different part in making real-time monitoring and analytics possible:

Technology | Role in Predictive Maintenance |

IoT Sensors | Continuously collect real-time data such as temperature, pressure, vibration, and humidity from equipment. |

Artificial Intelligence | AI algorithms analyze large datasets, identifying patterns that help predict future equipment failures. |

Machine Learning | ML models improve the accuracy of predictions over time by learning from historical and real-time data. |

Edge Computing | Processes data close to the equipment for quick, real-time decision-making. |

Digital Twins | Virtual replicas of physical equipment that provide a real-time, simulated view of the machinery’s condition. |

Cloud Computing | Provides scalability and enables storage, processing, and analysis of data across multiple systems and facilities. |

What are the Benefits of IoT-Driven Predictive Maintenance in the Manufacturing Industry?

The benefits of predictive maintenance extend beyond mere equipment health; they touch on operational efficiency, cost savings, and overall productivity.

Minimizing Equipment Downtime for Uninterrupted Production

Predictive maintenance helps manufacturers fix issues before they occur, reducing unplanned downtime by a large amount. Planned downtime can be used for repairs and part replacements, resulting in little to zero interruption in the production line.

Data from Statista show that predictive maintenance can reduce downtime by 30% and maintenance costs by 20%. This directly affects a business’s bottom line by making equipment readily available and increasing overall throughput.

Major Cost Savings Through Smart Maintenance

In traditional preventive maintenance, equipment is serviced at a fixed interval. Some equipment did not require a servicer but still got serviced, which increased the cost.

In predictive maintenance, equipment is maintained and repaired according to its needs. Issued equipment is detected with sensors; accordingly, that equipment or its part is repaired. Overall, unnecessary repair costs are saved.

A Deloitte report says that predictive maintenance can cut maintenance costs by 25% on average. Also, because parts are only replaced when they break, there is less need to keep spare parts on hand.

Extending Equipment Lifespan for Sustainable Operations

One of the principal benefits of IoT-driven predictive maintenance is machines’ longevity. Manufacturers can keep their eyes even on minor issues from turning into big ones by constantly checking the health of their equipment. With this, they can fix the issues as soon as equipment shows signs of worsening. This targeted approach not only makes equipment work better but also makes it last as long as possible.

In a time when efficiency and sustainability are very important, keeping machines running smoothly for longer periods helps reduce waste and make better use of resources.

Boosting Worker Safety Through Proactive Monitoring

Workers’ safety is very important in any manufacturing environment, and IoT-enabled predictive maintenance is key to making the workplace safer. Using advanced sensors and data analytics, manufacturers can easily find equipment problems early on that could put workers in danger.

For example, finding wear and tear on high-temperature machinery early on can prevent major breakdowns that could otherwise put people in danger. Companies create a culture of care and responsibility by prioritizing safety through predictive maintenance. This ensures that employees work in a safe environment that protects their health.

Driving Environmental Sustainability with Energy-Efficient Operations

It’s very important to consider how manufacturing processes affect the environment. IoT platforms are at the forefront of making operations more energy-efficient.

Predictive maintenance increases the output and ensures that machines work at their most efficient levels, lowering energy use.

Predictive maintenance can make the manufacturing process more environmentally friendly by identifying equipment breakdowns that require more energy. This focus on efficiency not only lowers costs but also aligns with efforts worldwide to encourage eco-friendly actions, making businesses seem like good planet guardians.

Common Challenges in Implementing Predictive Maintenance

Of course, predictive maintenance has many benefits, but using IoT platforms for predictive maintenance comes with a few challenges. Here they are:

High Initial Investment

When manufacturers implement IoT-enabled predictive maintenance in their plants, they have to invest upfront in sensors, connectivity infrastructure, and analytics tools. This investment is initially a bit difficult for small—to medium-sized manufacturers, especially when trying to implement such systems across multiple production lines.

However, companies that have already made a lot of savings for this business can make this initial investment.

According to a Gartner report, the return on investment (ROI) on predictive maintenance systems is usually seen in 12 to 18 months, depending on the implementation size.

Data Overload

Manufacturers may find it very hard to handle and process the continuous influx of data from thousands of sensors every second.

If they don’t have the right infrastructure for managing this huge data, important insights could be missed, which could mean missed maintenance opportunities.

In this case, cloud computing and edge computing are useful because they provide the tools needed to quickly process and analyze large datasets.

Integration with Legacy Systems

It is seen in many manufacturing environments that they have been using the same type of equipment for years. Those pieces of equipment are not designed to work with modern IoT sensors or platforms.

In this case, retrofitting legacy systems with IoT sensors can be challenging. It sometimes requires costly upgrades or big changes, which forces manufacturers to make another huge investment.

Data Security and Privacy

In the manufacturing industry, Internet of Things (IoT) systems are becoming more interconnected, which makes them more susceptible to cyberattacks.

Manufacturers face a significant challenge when implementing Internet of Things platforms for predictive maintenance: ensuring the security and privacy of their data.

How to Overcome the Challenges? Best Practices for Implementing Predictive Maintenance

The following recommendations for best practices can help manufacturers overcome the difficulties that come with implementing Internet of Things-enabled predictive maintenance:

Start with Pilot Programs

Start with small-scale pilot programs to see how well predictive maintenance works on important equipment. This way, manufacturers can determine the return on investment (ROI) and make the necessary changes before going live on a large scale.

Data-Driven Decisions

Always ensure that the data from IoT sensors is processed and analyzed correctly using advanced analytics tools. This will provide manufacturers with useful information for making decisions about maintenance.

Workforce Training

It is important to invest in training maintenance teams. This will help them better understand the data generated by the Internet of Things platforms and decide how to act on it.

Cybersecurity Measures

Implementing robust cybersecurity protocols, which include encryption, secure data transmission, and regular audits, can protect sensitive information from potential hazards.

Conclusion

The manufacturing industry is changing, and predictive maintenance is a must-have tool for modern manufacturers. IoT platforms make this change possible, giving manufacturers the tools they need to track, predict, and act on real-time data about the overall condition of their equipment.

As AI, machine learning, and edge computing improve, IoT monitoring platform will provide more accurate, cost-effective, and energy-efficient maintenance solutions. If manufacturers today adopt IoT-enabled predictive maintenance, their equipment will last longer. They will also be at the forefront of operational efficiency and environmental responsibility.

If you also want a better IoT platform, connect with us today.

With Thingsup, your benefits will be clear, challenges will be manageable, and the future will be bright. Our IoT platform will enable predictive maintenance and help you transform your business to a new level.